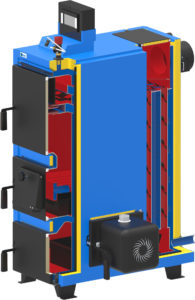

MAGA combined boilers enable the choice of several fuel types. The most wanted combination is the possibility to combine wood and pellets combustion in the boilers of the DP series. There is also a traditional combination with pellets, coal and grain waste combustion in PU boilers. The new PU range allows the combination of pellet, coal and wood combustion.

When the DP boilers are reasonable?

The most common motive for the choice of a combined boiler is the availability of fuel and the owner’s comfort at the same time.

The wood-pellet combination is most used in regions rich in wood or with the occasional reasonable prices. The DP series boiler enables:

- Combustion of wood, wood brickets, wood chips and wood pellets

- Wood log length up to 55 cm

- Automatic transition from wood to pellet mode

The pellet burner does not start until the wood/bricks/chips in the upper chamber is burnt out and the water temperature in the system does not decrease. Both combustion chambers are completely separated, the wood ash does not fall on the pellet burner.

When the PU boiler is the best choice?

Again, when a cheap fuel is available.

With the availability of high-quality coal in the form of an coal chips (fraction up to 25 mm), it is an economically efficient heating system. Hard coal with a calorific value of 28 MJ has almost twice the calorific value of wood pellets, while the price level of the bagged fragmented coal is at the price level of wood pellets. Fuel quality is very important. Coal containing rocks can damage the fuel feeder.

The PU system works with a retort feeder with and fixed container with a capacity of 200 (PU25) or 300 (PU50) liters.

Nowadays PU series are mostly used by the farmers to burn cereal husks from sewage treatment plant and waste cereals (oats, wheat, sunflower, etc.) and own waste mixtures. The calorific value of cereal waste is lower than that of wood pellets or coal.

Recommended boiler installation

The functional connection of the boiler depends on the quality of the design and installation of the heating system. Even the most efficient modern boiler will not function properly when there are the errors in mix setting, or buffer and pumps installed improperly.

Signs of deficiencies in the installation with an accumulation tank cause:

- Boiler effect – the heat does not enter the heating system directly but it primary heats the entire volume of the storage tank.

- Water whirling in the buffer tank

- Insufficient heating of the building as a result of the improper installation

Defects due to faulty installation of termo-valves to protect the boiler against low-temperature corrosion (to ensure return):

- Low temperature corrosion occurs – the termo valve does not perform its function

- Radiator effect – the boiler does not transfer heat output to the system, but only heats itself. It works as a separate radiator.